Fly catchers / Fly Killers

Fly catchers / Fly Killers

Characteristics

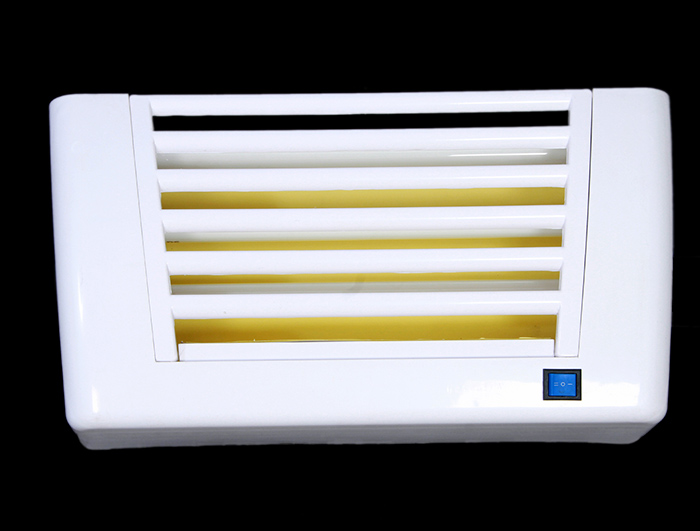

Fly Catchers (Insect Killer Machines) provide effective and hygienic protection against flies and other flying insects, ensuring a clean and safe environment. Designed for high-capacity performance with low power consumption, they are widely used in Restaurants, Hotels, Food Processing Units, Hospitals, Offices, Shops, Industrial Kitchens, Warehouses & more.

Product features:

– Light weight yet body is made of ABS plastic

– Stylish, compact design & aesthetic in look

– No toxins, no poison, no insecticides

– No contamination, no fragmentation of insects

– 100% safe for humans

– No high voltage, no risk of accidental electric shock

– Replaceable UVA Tube & glue boards

– Hygenic & Quite operation

– Ease installation and maintenance

Technical specification

Electrical

INPUT VOLTAGE: 220-24V50Hz

INPUT POWER: this is dependent on tune and no/ of tubes fitted.

DIMENSIONS AND WEIGHT

| Hight | 300 mm approx. | 11.80” |

| Width | 550 mm approx. | 21.60” |

| Depth: | 140 mm approx. | 5.50” |

| Weight: | 3.750 gms | 10lb |

| Cw315 | 3x15watt |

| Control boards | HM-23 2nos, HM-03 1nos |

| Insect attractant | UVA tube BL350 |

| Tube type | Actinic BL 15W x 3nos |

– Uses UVA tubes: highly attractive to insects but safe for humans

– No high voltage, grid, no “Zap” no risk of accidental electric shock

– No fragmentation of insects thus no contamination hazards in food processing, pharms units, hospitals, etc.

– Lightweight yet body made of ABS plastic – a permanent asset; no rusting associated with conventional metal models.

– Easy to maintain and services; click-on covers and easily replaced control (glue) boards