Fly Catchers & Fly Killers

Fly Catcher & Fly Killer Manufacturer in India

Cross Flow India is a leading manufacturer and supplier of high-performance fly catchers and fly killer machines in India, offering reliable and energy-efficient insect control solutions for commercial and industrial applications. Our UV fly catcher machines and electric fly killer systems are specially designed to maintain hygiene, prevent contamination, and support strict sanitation standards in food processing units, restaurants, hotels, hospitals, warehouses, retail stores, and pharmaceutical facilities.

Engineered with advanced UV light technology, durable ABS and metal body construction, and low-maintenance components, our commercial insect killer machines provide safe, chemical-free, and effective fly control. Whether you require a glue board fly catcher for hygienic food areas or a heavy-duty electric fly killer for industrial spaces, Cross Flow India delivers cost-effective, long-lasting, and high-performance fly control systems tailored to your operational needs.

What is a Fly Catcher?

A fly catcher is a glue-board based insect control device that attracts flies using UV light and traps them hygienically without fragmentation. It is ideal for food industries, kitchens, bakeries, and clean rooms where silent and chemical-free operation is required.

Key Features:

UV light attraction technology

Replaceable glue boards

No electric shock

Silent operation

Safe for food areas

What is a Fly Killer?

A fly killer machine uses UV light to attract insects and eliminates them using an electric grid system. It is suitable for warehouses, loading docks, outdoor areas, and commercial spaces where strong insect control is required effectively and efficiently.

Key Features:

High voltage grid system

Powerful insect attraction

Durable metal body

Easy cleaning tray

Low power consumption

Applications Of Fly Catchers / Fly Killers

Fly Killer for Food Industry → Widely used in food processing units, restaurants, commercial kitchens, and bakeries to prevent flying insect contamination. It helps maintain strict hygiene standards, improves food safety, and supports compliance with health regulations.

Fly Killer for Warehouses → Ideal for large storage areas, godowns, and loading docks where frequent door movement allows insects to enter. It effectively controls flying insects and protects stored goods from contamination and damage.

Fly Killer for Factories → Helps maintain a clean and safe production environment by eliminating flies and other flying insects around entrances, assembly lines, and operational zones, ensuring better workplace hygiene.

Fly Catcher for Hospitals → Suitable for hospitals, clinics, laboratories, and other sensitive areas where silent and hygienic insect trapping is required. Glue pad type fly catchers ensure safe operation without noise or insect scattering.

Fly Catcher for Commercial Spaces → Perfect for shopping malls, offices, retail stores, and showrooms to maintain a clean, pleasant, and insect-free environment for customers and staff members.

Fly Killer for Outdoor Areas → Designed for semi-outdoor spaces, industrial premises, loading bays, and open work areas where strong and effective insect control is required for better sanitation and comfort.

Product Features & Benefits

- Lightweight & Durable: Made from high-quality ABS plastic for strength, durability, and long service life.

- Elegant & Compact Design: Modern, space-saving design that complements any environment.

- Chemical-Free Operation: Functions without toxins, poisons, or insecticides — safe for humans and the environment.

- Hygienic Performance: Prevents contamination and ensures no fragmentation of insects.

- Safe & Reliable: Operates without high voltage, eliminating the risk of accidental electric shock.

- Replaceable Components: Equipped with UVA tubes and glue boards that are easy to replace for consistent performance.

- Quiet & Efficient: Ensures noise-free operation suitable for both commercial and residential settings.

- Easy Installation & Maintenance: Simple setup and effortless cleaning, reducing downtime and maintenance effort.

Technical specification - Electrical

- Easy Installation & Maintenance: Simple setup and effortless cleaning, reducing downtime and maintenance effort.

- Effective Insect Control: Attracts and traps flying insects permanently using replaceable adhesive (glue) boards for hygienic and efficient operation.

- UVA Tube Technology: Equipped with UVA tubes that are highly attractive to insects yet completely safe for humans.

- Shock-Free Operation: Functions without high voltage or electric grids — no “zap” sound and zero risk of accidental electric shock.

- Hygienic & Safe: Prevents insect fragmentation, eliminating contamination risks in food processing areas, pharmaceutical units, hospitals, and other sensitive environments.

- Lightweight & Durable Design: Constructed with high-quality ABS plastic, ensuring long life and corrosion resistance — unlike traditional metal models.

- Easy Maintenance: Designed for effortless servicing with click-on covers and easily replaceable adhesive boards, minimizing downtime and upkeep effort.

FAQ About Fly Catchers / Fly Killers

Q1: What is the difference between fly catcher and fly killer?

Fly catcher uses glue boards for hygienic trapping, while fly killer uses electric grids for instant elimination.

Q2 : Which is better for restaurants?

Fly catcher is recommended for restaurants and food areas because it prevents insect fragmentation.

Q3 : How much area does a fly catcher cover?

Coverage depends on model size, typically ranging from 300 sq ft to 1000 sq ft.

Q4 : What is the maintenance cost?

Maintenance is low and mainly involves replacing glue boards or UV tubes periodically.

Q5 : What is the price of a fly catcher in India?

Price varies based on size, UV capacity, and model type. Contact us for the best quotation.

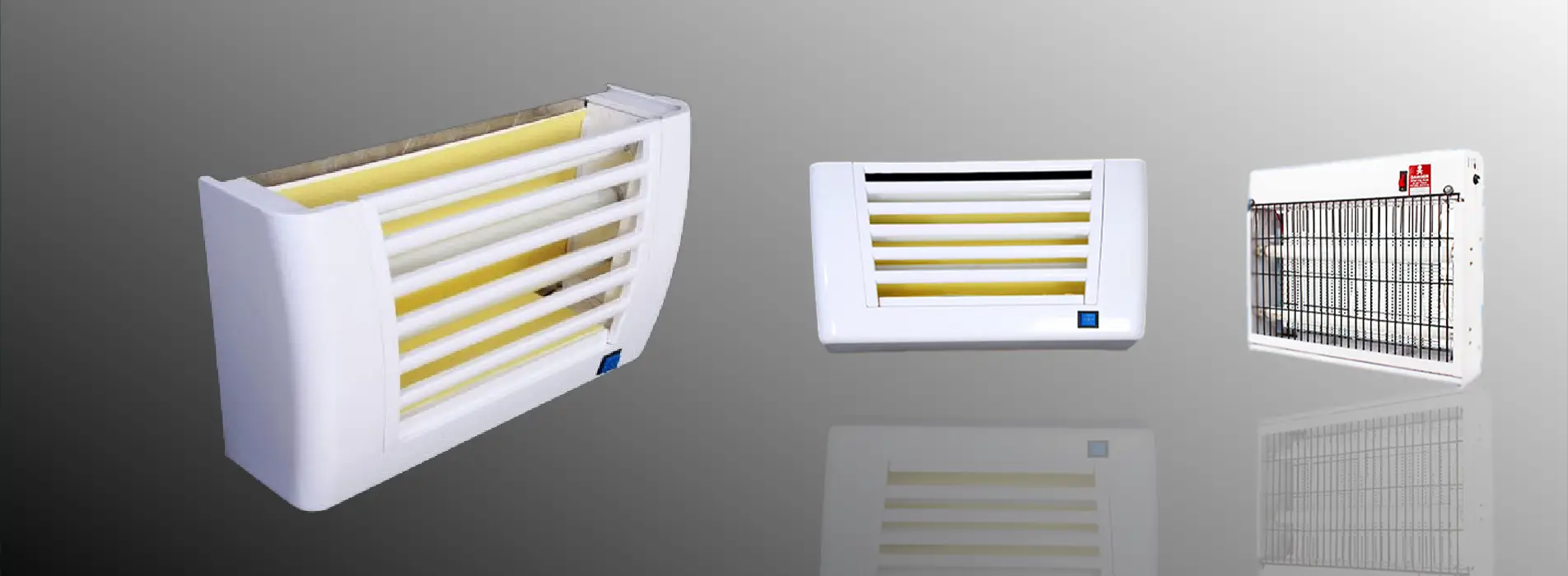

Products Showcase

Fly Catchers / Fly killers

Fly Catchers / Fly killers